It’s research team started with a simple supercapacitor made from carbon-based electrodes with a sulphuric acid electrolyte.

While not a commercial formulation, it is “one kind of which is mostly researched in the conventional supercapacitor literature” Jun Young Cheong, of the university’s James Watt School of Engineering told Electronics Weekly.

After 30,000 cycles at 4.0mA/cm2 , the reference capacitor only had 58% of its initial capacity left.

The tree back extract exudes from the bark of the cochlospermum gossypium tree.

Called gum kondagogu, it is a polysaccharide which turns into a conjugated biopolymer dubbed ‘KS’ when reacted with sodium alginate.

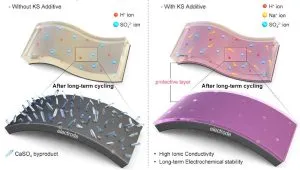

When KS is added to the sulphuric acid electrolyte, it passivates the carbon surface.

“The KS layer helped prevent physical degradation of the electrodes while still allowing the ion transport process which enables the supercapacitor to charge and discharge,” said the university.

After 30,000 cycles, the KS-modified capacitor maintained 93% of initial capacity.

“The gums we’ve used in this study don’t have many practical uses, and are actually a bit of a headache for the Indian government to dispose of,” said Cheong. “With this research, we’ve found a way of making something genuinely impactful from this gum, creating a biodegradable, recyclable biopolymer which enables remarkable performance and could extend the useful life of supercapacitors dramatically.”

Glasgow worked with Ajou University, Chung-Ang University, Myongji University and Amrita University.

The work is described in ‘Long-lasting supercapacitor with stable electrode-electrolyte interface enabled by a biopolymer conjugate electrolyte additive‘, published in Energy Storage Materials, which can be read in full without payment.