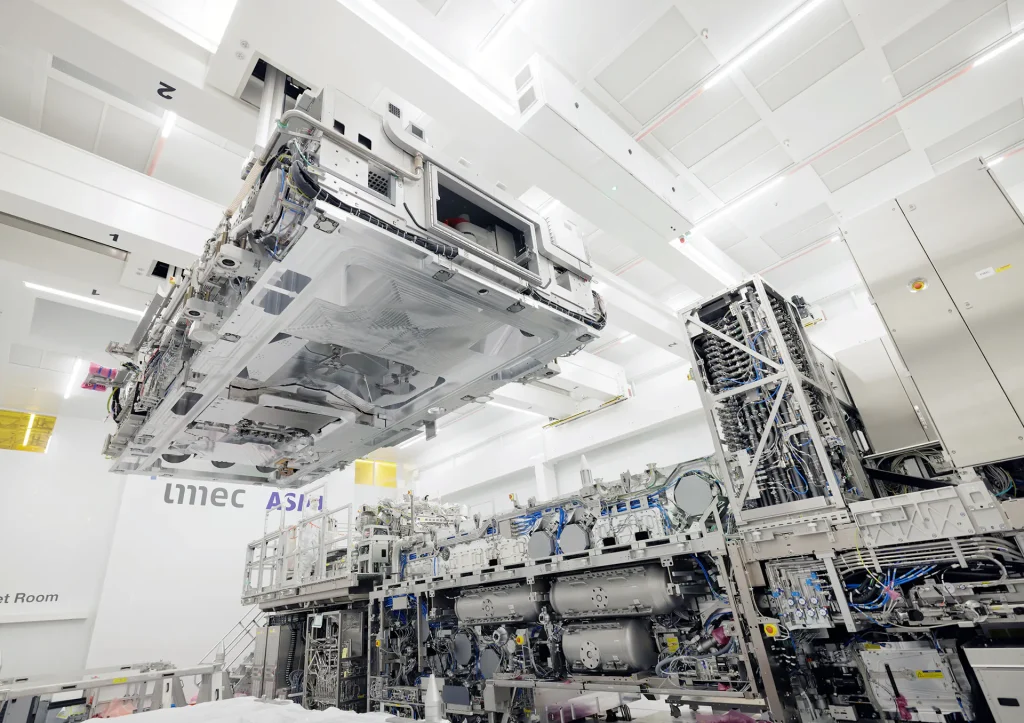

“The first High-NA EUV scanner has been assembled by ASML and the first wafers will be exposed soon,” says Steven Scheer, senior vice president of Advanced Patterning, Process and Materials at imec, “in the next few months, the joint imec-ASML High-NA EUV Lab will be operational, and access will be provided to the High-NA customers.”

“The High-NA EUV lab, with the installed equipment and processes, enables an early start of High-NA EUV learning for the customers before tools are operational in their fabs,” adds Scheer, “it has been imec’s role, in tight collaboration with ASML and our extended supplier network, to ensure timely availability of advanced resist materials, photomasks, metrology techniques, (anamorphic) imaging strategies, and patterning techniques.”

Field stitching is a key enabler in High-NA: field stitching is needed because of the anamorphic lens (i.e., a lens with different de-magnification in the x and y directions), resulting in field sizes of half of the conventional scanner field size.

Imec will share the latest insights that enable at-resolution stitching based on work done with ASML and our mask shop partners on imec’s NXE:3400C scanner. At-resolution stitching will reduce the need for design changes to cope with the field size reduction.

On the material and process side, it is clear that metal-oxide resists (MORs) are still in the lead for metal line/space patterns. Imec will present the advancements of MOR in terms of EUV dose-to-yield reduction. The selection of the specific underlayer, optimization of the development process, choice of mask absorber, mask bias and mask tonality were leading to a more than 20% dose reduction for lines and spaces, without increased roughness or stochastic failures.

Also, tip-to-tip dimensions were not negatively impacted by these dose reduction activities. The dose reduction work continues and is highly appreciated by our chip makers, since it leads to EUV cost reduction due to the higher scanner throughput.

An unexpected result was obtained by using MOR resists with a binary bright field mask for contact hole patterning. A 6% dose reduction with a 30% local CD uniformity (LCDU) improvement was achieved after pattern transfer when comparing to a positive tone chemically amplified resist (CAR) and a binary dark field mask transferred in the same stack.

A remaining concern of bright field masks for contact holes is the mask quality and defectivity. This will need careful investigation to make MOR an option for contact holes. Until then, positive tone CAR resists with dark field masks will be the leading candidates for contact and via patterning in High-NA EUV.

High-NA also requires improvements in metrology and inspection, giving the higher resolution (by the high NA) and thinner films (by the reduced depth of focus (DOF)). Imec’s results on e-beam and deep-UV (DUV) inspection show that new best-known methods (BKMs) are in place to find High-NA-relevant stochastic patterning failures, such as hexagonal contact holes.

Several machine learning techniques (based on denoising SEM micrographs) are proposed to facilitate the small defect inspection and classification.

Imaging improvements through source-mask optimisations and anamorphic mask OPC (considering the need for stitching) will be presented by imec and partners.